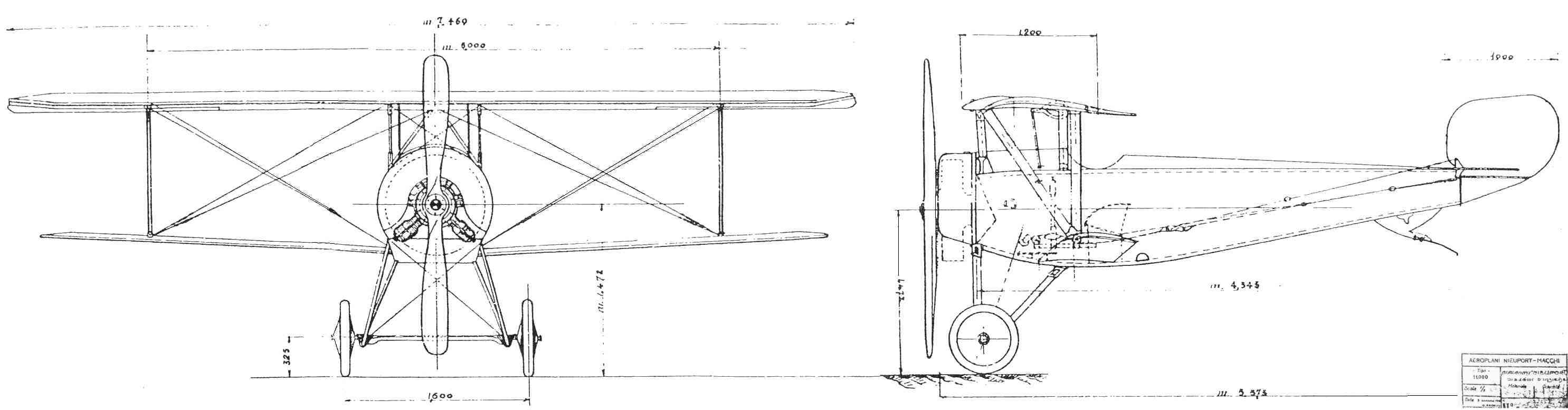

• Building a Nieuport 11 replica •

Construction of a fuselage is normally straightforward and consists of building each side flat on a table.

The Nieuport 11 has a complex fuselage form however, with a sudden change in taper to the rear when viewed in plan view.

It has front longerons curving towards each other when viewed in elevation but the rear longerons curve together in plan view.

The bottom longerons are closer than the top ones, giving a slight 'V' section to the fuselage.

Therefore to achieve an exact scale look the fuselage had to be assembled on a jig, with the longerons separately laminated and the frames built individually.

The top and bottom front longerons are curved towards each other, and the rear longerons are curved towards the centreline.

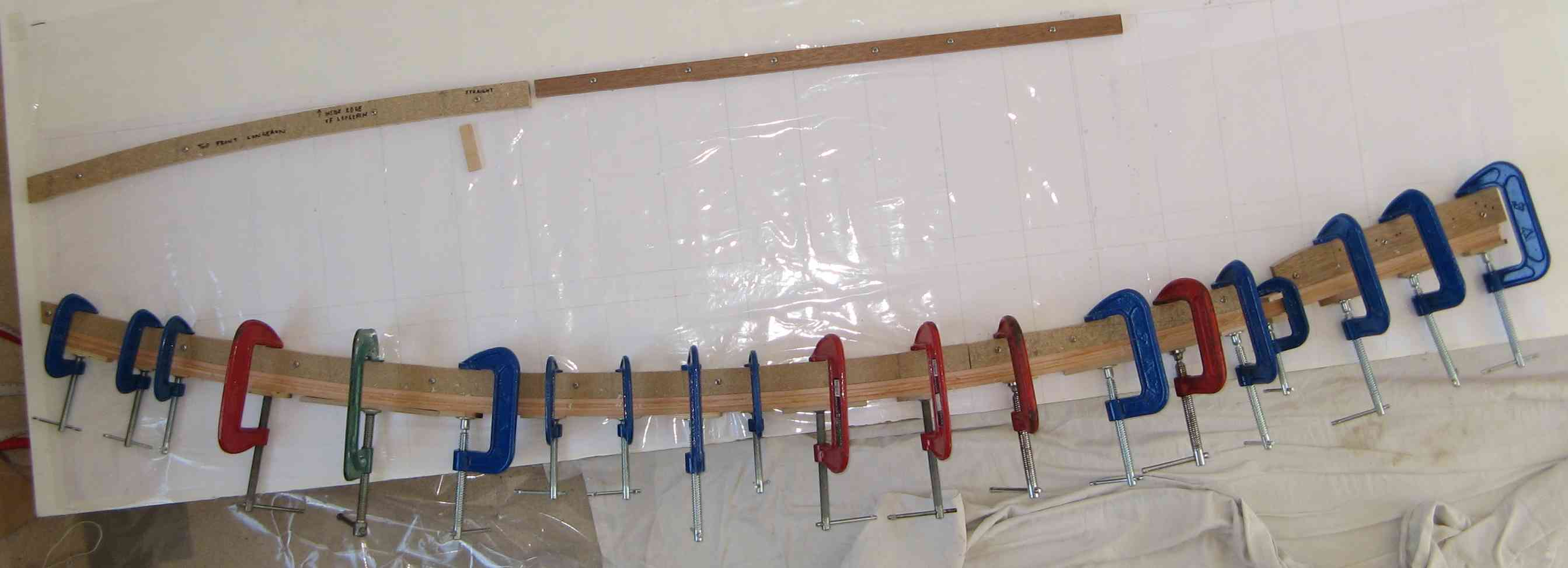

Consequently these all needed to be laminated and the sections scarfed together.

The completed longeron sections awaiting scarfing.

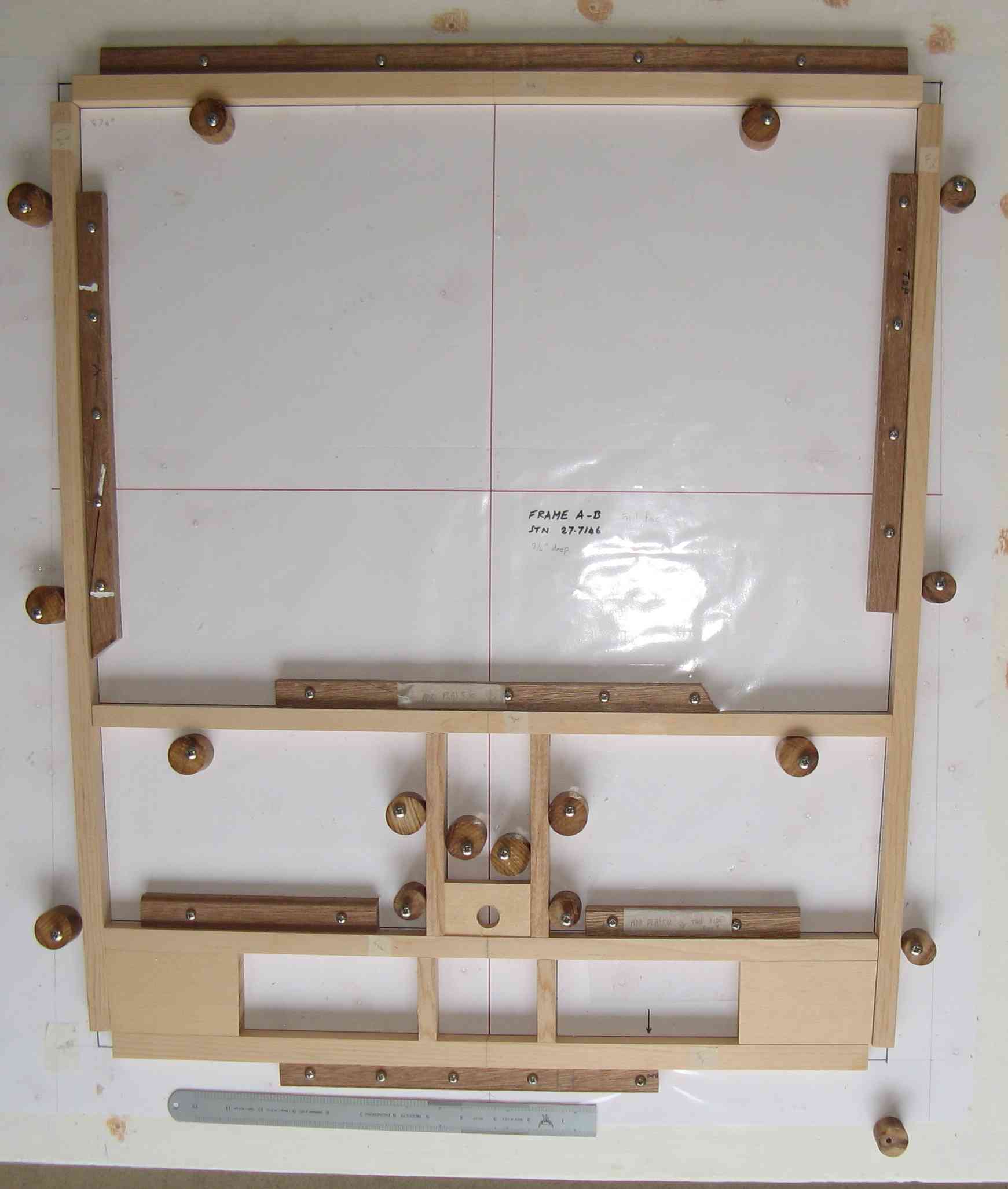

The table has been cleaned up from the previous components and a fresh sheet of plastic laid on top, with the fuselage pattern laid in in marker pen.

The frames were built individually to exact dimensions.

They would have to be bevelled later.

Blocking for the wing attachments and controls was built in.

The frames were set up on a jig.

The longerons were scarfed and fitted in place.

Diagonals were then cut to the correct angle and glued into place.

The seat is a simple ply arrangement. Leather effect foam cushions will make it more comfortable! The rear backrest hinges to allow access to the rear fuselage.

The base is screwed to the runners and so the whole assembly can be removed.

The rear cabane struts are attached to the fuselage with steel brackets. There is an aluminium insert inside the strut to add strength.

The upper ends of the cabane struts are attached to the wing using machined aluminium inserts.

The turtledeck is built in the same manner as the Minimax.

This comprises a double frame at the front and rear of the fuselage. Only the internal frame is slotted, thus the stringers are not visible externally.

The gap between the frames will be covered with ply.

There are two intermediate turtledeck frames which are both 1/2" short of the stringers.

After lining up the stringers with string lines and by eye, slotted gussets are glued in place to attach the stringer to the frame.

The front turtledeck.

A lip has been added around the fuel tank neck to prevent spills entering the fuselage. A small hole in the fuselage side within the fuel hatch will allow spills to drain overboard.

Also shown are the laminated cheek pieces that will attach to the front fuselage sides next to the firewall, creating the circular cowling shape.

The fuel tank was fabricated by Compbrake Motorsport.

It is mounted on a platform with side supports bolted to the fuselage side. Consequently the whole assembly can be removed and the tank extracted through the cockpit opening if necessary.

Holding down straps will be added.

The filler sits below the level of the front turtledeck. A hatch will permit access.

There is a vent tube, inspection hatch and sight tube.

The first front side fuselage ply glued in place.

A hatch allows access to the rudder pedals, fuel hoses and tank.

Note the step (on the port side only) reinforced with aluminium.

The vertical slots are for the lower wing attachment brackets.

The step on the port side comprises an internal moulding and external aluminium trim.

The moulding is fibreglass, created over a balsa mould.

The firewall and front turtledeck in place temporarily.

The circular frame is laminated.

The turtledeck will be covered with 1/16" ply. The side cheeks will be aluminium.

The fuel filler hatch.

Edge holes allow fuel spills to flow overboard and the lip prevents fuel from entering the cockpit.

The wooden pins engage with holes in the cover. The outside edge is hinged. Removing the hinge pin secures the hatch.

The basic fuselage prior to fitting the turtledeck. The building table has been dismantled.

Lower wings are hanging on the wall.

The main wings are on the floor.

Clamping and strapping the front turtledeck in order to trim the edges.

Several trial fits are necessary.

The location of fittings is marked. Patterns were made to show where cables passed through the decking.

The Horizontal strip of timber has been fixed temporarily using the holes for fittings. This provides a base for the straps.

Glueing the front turtledeck.

Clamps and straps hold the ply flat against the frames.

Plastic sheet protects the straps from the glue. The edges are stapled to hold them down.

The staples are inserted through thick plastic to aid removal without damaging the ply.

Completed cockpit.

The ply is just 1.6mm. This is reinforced around the edges as this is where the pilot will grip when mounting and alighting.

The scalloped edges of the rear turtledeck can be seen.

The map holder is visible on the starboard side of the cockpit.

Front turtledeck.

Holes for the cabanes, aileron cables and front cross-wires have been made.

The deck will be varnished after the windscreen support has been added.